Our Quality Assurance

Our team has direct collaboration with quarries ensuring the selection and smooth supply of sound blocks required for any type of projects. After the cutting, the slabs are taken for further processing. The process of grinding and mirror polishing or the antique finish is done using a 20- head automatic polishing machin eavailable at our various facilities worldwide.

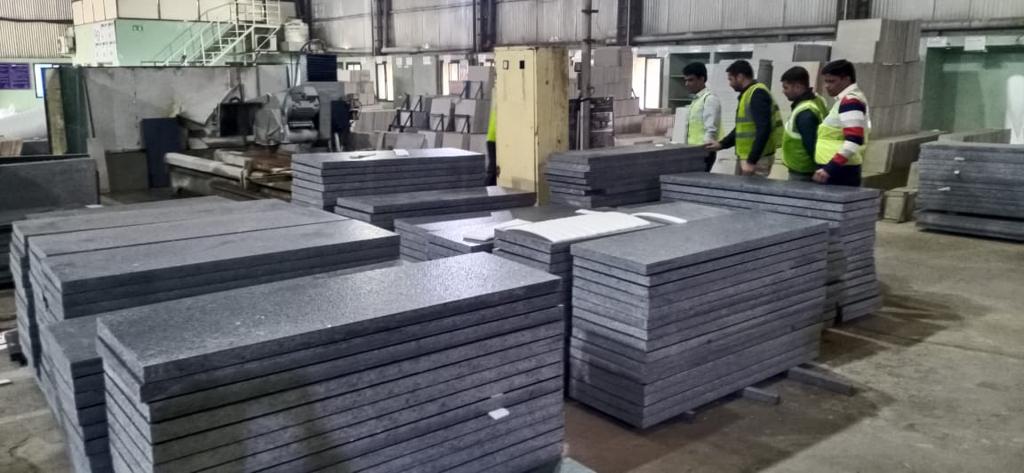

Before the final product reaches you and after final finishing, our quality control team inspects the material for quality checks post which the passed, the material is packed under proper supervision and dispatched from our various factories.

Quality becomes an eminent factor during the processing of the marble, travertine, granite, or any other stone products. From stone’s size to surface finish, texture, stain, and any other visible defects, each stone slab is checked thoroughly to grade the same homogeneity before final edge cutting.